Our Featured Services

Services Strata Buildings

[ Revma does programmed maintenance on building and service all there ] ● Storm water pits ● Pressure system ● Grease traps systems ● Water reuse systems ● Sewer pits

Control Panel Building

[ We build control panels your job your requirements and our team will build to suit. ] ● Vsd motor controls ● Pump station controls ● Weather station controls ● Storm water station controls ● Filtration systems

Labor Hire

[ We are fully insured and can do electrical shift cover for factories. ] ● Sara lee ● Boral ● Coca cola

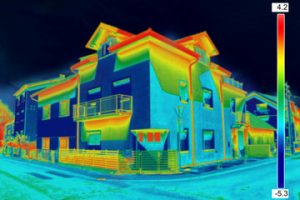

Thermal Imaging

Thermal imaging has quickly become a common practice in electrical maintenance and, when performed correctly and in conjunction with other electrical testing methods, an accurate analysis of the condition of electrical equipment can be made. This is why Revma offers thermography as a part of our Preventative Maintenance Program, placing significant importance on the results it presents. Find out more now!

What is Thermography?

As humans, we have an extremely limited visible spectrum, with electromagnetic radiation in the form of wavelengths being unable to be viewed by people normally. This is where thermal imaging cameras come in – they extend this visible spectrum, which produces an image on a camera screen that we can see. This technology allows us insight into the heating characteristics of electrical equipment and, by analysing the heat signatures present, we begin to get a grasp of how efficiently an electrical system is functioning.

Why use Thermography?

When utilized in conjunction with live electrical testing, Revma can use thermography to pinpoint very particular functioning errors of equipment which is extremely beneficial for the smooth operation of plant and equipment. This is one of the main reasons that we use Thermography as part of our Preventative Maintenance Program.

Additionally, the benefits of thermography far outweigh the potential costs of replacing large electrical assets due to poor maintenance practices. Some benefits include:

- Early detection of electrical faults.

- Trending of electrical faults as they progress from minor to severe.

- Accurate fault detection resulting in the correct action of repair.

- Photographic evidence which provides a visual representation for reference.

- No interruption of supply or to business operations.

- Reduced risk of electrical fires.

- Assists with insurance compliance requirements.

- Offering peace of mind in knowing your installation is safe and reliable.

Detecting electrical faults using Thermography

Thermography can also detect a large variety of electrical faults including:

- High resistance terminations due to loose connections.

- Excessive loading of electrical accessories and cabling.

- Faulty internal contacts on small & large switchgear.

- Excessive current and voltage harmonic distortions.

Thermography completed by professionals

When utilized effectively, thermography can save businesses thousands of dollars on repairs, not to mention the huge production losses caused by equipment failure. But, in order for it to offer the benefits above, thermography needs to be completed by an appropriately trained technician.

We are able to both understand and fully analyse the data that is presented through the thermography testing, which leads to a correct and comprehensive diagnosis of faults. Revma technicians are able to pinpoint the exact reason why a piece of equipment is not functioning efficiently, and then provide a complete report as to what they recommend for repair.

Knowledgeable Thermography experts

At Revma, our technicians have been trained to the highest standards in the industry over many years. This ensures that we can effectively and efficiently assess both simple and complex problems, which results in accurate diagnosis and cost-effective solutions for businesses of all sizes. If you think your business can benefit from using thermography give us a call on 0448 473 863 to see how we can help